NAME OF PROJECT: Hydraulic and Control System

LOCATION: Kilburn, SA & Brisbane, QLD

CONTRACT PERIOD: August 2014 - May, 2015

CLIENT: CF Rail Services

SERVICE:

A turn-key design, manufacturing and installation of Hydraulic and Control System on a Rail Transportation Train for the CF Rail Services (the main contractor for Queensland Railway).

SCOPE

Torque Industries have designed and manufactured a hydraulic and control system for remote clamping of rails on six wagons, for transport purposes. The train can carry 24 rails 110 metres long at a time. The system consists of two independent hydraulic power units (driven by diesel engines), control valves, pressure lines, cylinders and instrumentation, as well as a suite of equipment for wireless and remote radio control. The system provides comfortable interfaces for the operator through colour touch-screens. One of the challenges of the project was to accommodate all the equipment, including hundreds of hoses, cables and multiple electrical cabinets within the chassis of the wagons. Another was to provide convenient and safe access to all control valves for manual operation, in case of electrical problems.

OUTCOME:

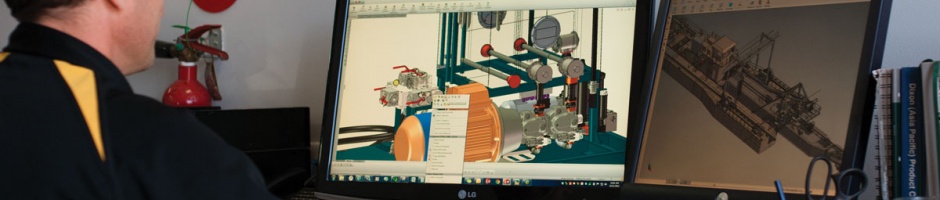

The remote hydraulic clamping of rails was the first of its kind in the world. Hence it also required a specialised solution to energise and control the system. During the design stage, 3D modelling was performed and demonstrated that the multiple hoses would fit in some locations only if a special, compact type hose would be used. The drawings were also used effectively to assist installation of the valves and the pipe work. Electrical simulations were performed as well and highlighted a need for relatively heavy cross sections of the cables (to reduce voltage drop). The system has been commissioned successfully, first in Adelaide and then in Brisbane.

FEATURES:

TESTIMONIAL: by Ming Lin | Mechanical Engineer | CF Rail Services

This is not an easy project and Torque team has done an excellent job in attending to problems. A great system being the first of its kind in the world designed and manufactured in Australia. Prompt and good after-sale support was demonstrated by Torque team.

Phone: +618 8341 0177

Map and full contact details