LOCATION: ASC Shipbuilding Hub, Outer Harbour, SA

CONTRACT PERIOD: January - April 2018

CLIENT: ASC AWD Shipbuilding

SERVICE:

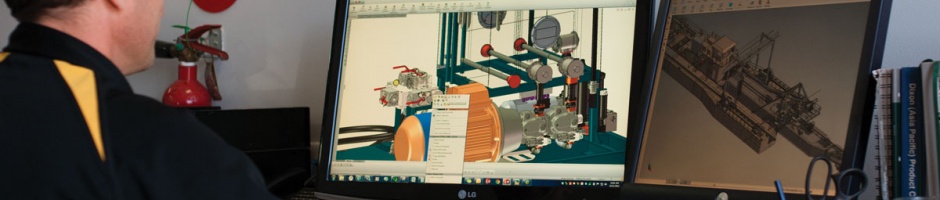

Design, manufacturing, installation, and commissioning of hydraulic and electrical control systems

SCOPE:

The purpose of this Diesel Flushing Rig was to remove contamination from the pipework installed on the Air Warfare Destroyers, to achieve the required level of cleanliness.

It consisted of a double wall, stainless steel diesel reservoir, a screw pump, a centrifugal separator, a basket strainer, a bag filter, a ventilation fan, visual and electronic monitoring devices, and related pipework and cables, accommodated in a 10’ Cargo Container.

The flushing system was commissioned successfully, and provided high water removing and filtration capacity of diesel fuel, with minimum requirement for labour, due to automatic self-cleaning capability. All the equipment, other than the tank, was accommodated in a small container, so that the unit could be moved to other locations and positioned in areas of limited space. Despite being relatively small and compact, good access to the equipment was provided by installation of additional doors on both sides of the container.

FEATURES:

Phone: +618 8341 0177

Map and full contact details