LOCATION: Bowmans Rail, SA

CONTRACT PERIOD: July 2017 – May 2018

CLIENT: Balco Australia

PROJECT: BL3 Hay Press – 100kg bale

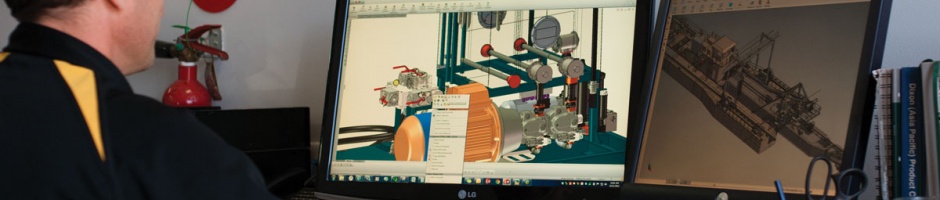

SERVICE: Design, manufacturing, installation, and commissioning of hydraulic and automation systems

SCOPE: Torque Industries have provided a turn-key solution for the client to process variates of agricultural products by forming 100kg bales in a demanding cycle of 14 seconds. The project required close cooperation with Balco Project Management, Schutz Industries – press fabricator, Technigraphica – press designer, Nordon Cylinders – cylinder manufacturer, Parker – hydraulic equipment manufacturer, NHP – electrical equipment supplier, Turck – instrumentation supplier, pressure pipe fabricators, and other contractors, as well as coordination of own resources.

The following sub-projects can be identified:

- Hydraulic Power Unit (HPU) which included: 770kW of power (7x110kW) for Press and Multibale, and 44kW for oil filtration and circulation, an 8000-litre hydraulic oil reservoir assembly with monitoring instrumentation, 400kW nominal capacity Water Cooling System, ventilation system and a shed,

- Manifold assembly with industrial hydraulic control valves, high and low pressure pipework and hoses

- Hydraulic actuators, ie cylinders and motors to operate all functions of the press,

- Electrical automation system, including assembly of control cabinets, and programming of the hay processing line, HMI and a safety system to Cat 4.

- Documentation: hydraulic schematic and parts lists, commissioning instructions/report, technical data, electrical diagrams, cabinet layouts, alarm messages, etc.

OUTCOME:

The fastest operating press of the 100kg bale capacity in Australia, regularly achieving cycle times below 14 seconds. Impressive installation due to extensive use of hard pipes fitted in aesthetically pleasing arrangements

FEATURES:

- Pressure compensated pumps used for maximum energy efficiency.

- High performance proportional control valves used for fast operation and high precision of motion control of selected cylinders.

- A battery of hydraulic accumulators used for better utilisation of installed power.

- Manifold assemblies used for maximum integration of the hydraulic system.

- Line de-pressurisation system used to ensure no pressure present in the pipework after a shutdown.

- Hydraulic safety valves used for local isolation of equipment, i.e. Press Strapper and Multibale.

- Real time process animation.

- On-line access and monitoring of the control system

- And more