LOCATION: Mobile (Australia Wide)

CLIENT: Halliburton Pty. Ltd.

SERVICE PROVIDED:

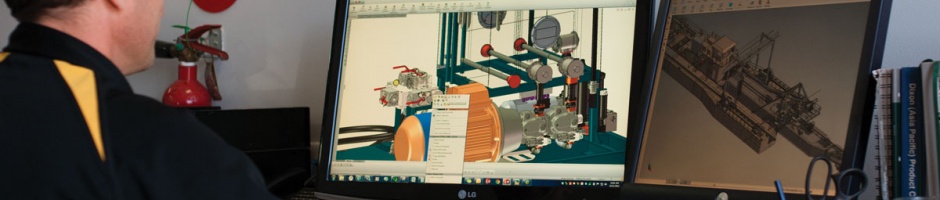

Complete hydraulic design, manufacture and commissioning of HPS (Hydraulic Power System) - to operate a Quad Blow Out Prevention System (BOP).

SCOPE:

Halliburton contacted Torque at the eleventh hour; they required a HPS to operate a QUAD BOP in a remote region of Australia. An existing system was in use in another location and the new program had to go ahead.

Torque completed the preliminary design within days of the original request. The scope and operational requirements of the customer were incorporated into the solution, an agreement on value and timeline was completed, and the work began.

The HPS had to provide emergency backup hydraulic capacity in the event of other system failures. The unit was required to be located close to the well head and for this reason an alternative pumping solution was required as electrical equipment could not be used in close proximity of the well head.

A small pneumatically operated pump system, incorporating a series of large accumulators, was required to allow rapid discharge on hydraulic fluid in the event of system failure.

Operational valves were fitted within the main cabinet increasing both the safety of operation and minimising the risk of fluid leaking on to a sensitive environmental area.

.FEATURES:

OUTCOME:

The project was reviewed by the client at Torque's premises to gain operational approval prior to dispatch. The final project was delivered on time and utilised immediately on site, resulting in a successful outcome.

Phone: +618 8341 0177

Map and full contact details