LOCATION: ASC – North, Osborne

CONTRACT PERIOD: 6 months

CLIENT: Australian Submarine Corporation (ASC)

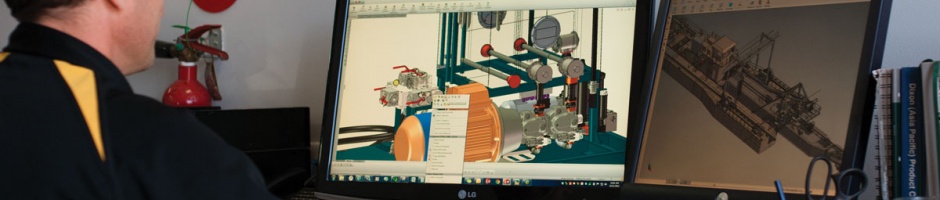

SERVICE: Submarine Lifter – Transfer System Refurbishment

SCOPE:

The transfer bogies and load monitoring systems had been in service for over 25 years and although regularly maintained more significant repairs were required. To this end there was a requirement to inspect and assess the condition of all bogies (43 in total) and carry out repairs to ensure all bogies continue to operate safely, effectively and reliably in the future.

Along with this equipment, a Load Cell Control Consul System was upgraded replacing the existing 40-unit load meters with an electronic screen which is capable of providing data logging such that loads are recorder against time. The new screen also shows alarm set points and history.

A purpose-built bogies test rig used for calibrating load cells and setting of the decent rate of hydraulic lift cylinders on the was refurbished, strengthened and modified. FEA testing was conducted to ensure the rig was capable of withstanding the forces generated. A hydraulic cylinder and power pack were added to the rig to provide a constant load to set the bogie lift cylinders decent.

OUTCOME:

With consultation and cooperation from ASC personnel, all work carried out on the transfer system was completed and tested prior to leaving our workshop and has since lifted the submarine at ASC successfully.

FEATURES:

Phone: +618 8341 0177

Map and full contact details